News

Thode acquisition of JD Saw & Supply Ltd

4th February 2025

To All Customers and Suppliers

Subject: Acquisition of JD Saw and Supply Ltd by Thode Knife and Saw Ltd

Thode Knife and Saw Ltd have purchased the assets of JD Saw and Supply Ltd, including predominantly inventory and equipment associated with selling of saws and consumables for the sawmilling industry in Canada.

The acquisition is effective from February 1st, 2025.

The acquisition includes the staff, customer base, and supplier alliances including Jeff Bickford being appointed as sales manager for Thode Knife and Saw Ltd Canada.

Our products will now include the well known brands of Sharp Tool and Cortex that JD Saw & Supply has successfully promoted and grown in Canada. Combining this with Thode’s products including world class Iseli filing room machinery our offering is more complete backed up by a great team of experienced staff.

JD Saw and Supply Ltd will no longer be trading as an entity and from 1st February 2025 all sales and purchases will be made in the name of Thode Knife and Saw Ltd. ( a separate legal entity ).

We thank all customers for their support and trust that the support of the combined organisation will be continued.

If you have any further questions in regard to the transition of current orders or setting up of new accounts, please contact Jeff Bickford on Ph 250 981-1968 or jeff@thodecanada.ca

Kind Regards

Adrian Hoogeveen

CEO

Iseli BNF100 @ Pan Pac Otago

The latest Iseli machine installation has just taken place in August 2024 at Pan Pac Otago with the BNF100 4 axis bandsaw side grinder now in operation.

After only a few hours of setting up, we had the first saw on the BNF ticking around testing and tuning.

Just last year Pan Pac invested in a Iseli KHF100 circular saw side grinder. This meant the training on the new BNF100 was super easy as the team was already up to speed with how the machine operated, and they only required a few pointers on the loading and unloading process.

This machine side grinds each tip from start to finish before feeding the next tooth, with the number of passes, amount to be taken off, and the grinding speed for each pass being preprogrammed, resulting in incredible consistency.

At 1800 kg there is no arguing that this machine, along with the rest of the Iseli range, is of heavy duty, rigid construction, that translates into accuracy!

Being fully programmable with the ability to save individual recipes for each saw on site makes operation extremely easy.

When chasing sawmill performance, accurate tip geometry is key and the Iseli BNF100 hits the mark every time.

Thode would like to take this opportunity to thank Pan Pac for their continued support and loyalty to the Iseli range of machinery.

MAIN PICTURE:

Pan Pac Otago Saw Doctors, Caebian Pahl & Phil Lockhart with the latest Iseli BNF100 side grinder.

Another RZ1 at West Fraser Quesnel

This Iseli RZ1 automatic level & tensioning station at Quesnel BC was sold and commissioned by Phil Higgins of Thode Canada.

Wesley Loper, the head filer is extremely pleased with the machines. He states they greatly out performed other brands of machines that he had previously worked with and was looking forward to the consistency this machine offers.

ISELI has set new standards on the world market with its fully automatic straightening centre. The band saw blades can be clamped, levelled and straightened in one set-up. The measurement takes place over the entire saw blade by means of high-resolution sensors. This process is patent-protected and guarantees the best results.

Staff from the left are Leroy Schwandt, Kelly O'Hara, Mike Vipond, Yeremy Lambert and Wesley Loper (head filer)

Thode Canada and Iseli thank West Fraser for their continued support at their Sawmill Sites in BC & Alberta as they upgrade their Filing rooms with world class Iseli equipment.

For any information on the Iseli range of products, please contact your Thode sales-rep

Rosvall Sawmill’s New Piece of Magic

At the end of June, after a short 8 month wait the Installation of the new look ISELI BNP100 CNC profile grinder took place at Rosvall Sawmill.

Purchasing this machine was justified after a very successful trial of the Thode VPD bandsaw profile back in early-October 2023, that is yielding a 15% gain in production since the mill has been running the Thode VPD saws full time since then.

The boys at Rosvall had the machine in place with power and air on and ready to go.

Monday afternoon the machine was powered up, test run and the recipes for the VPD double cut head rig and resaws programmed.

Tuesday morning after a few small adjustments the first saw was on and grinding, we found an issue with the feed finger later that afternoon. After shooting an email away to the Iseli service team in Switzerland we had the reply later that same evening and the following day a setting was changed, and the BNP was in full flight! The back up and support that Iseli provide is outstanding!

Wednesday morning, Adam and Tai, the Saw Doctors at Rosvall were into the training, boots and all, very quickly picking up the operation of their new bit of kit as they had already taken advantage of the opportunity to spend time at Thode Rotorua a few months prior training on our BNP100.

“It’s so easy to stay on top of the grinding with this machine and the reliability to just set and forget and know you will come back to a sharp finished saw is a whole new world over the old # 4 Armstrong.

The install went smoothly and caused no loss of production, and we had saws grinding within 2 days.

"The cleanliness of not having grinding dust everywhere is also a nice bonus and makes saw shop upkeep a bit easier also” Adam Mc Donald – Head Saw Doctor at Rosvall Sawmill

A big thank you to the team at Rosvall Sawmill for putting their trust in Thode to deliver another successful Iseli installation.

Iseli Machines commissioned at Tolko Sawmills BC

Tolko Lake View, Williams Lake, BC.

The Iseli RZ-1 benching station was installed April 2024.

Below: Robin Dieck, head filer.

Below: Jeremia Johnston, filing room supervisor.

Tolko Lavington, Coldstream, BC

Coldstreams RZ1 was also commissioned in April 2024

Matt Graves, head filer (left) with Shaun and Taylor

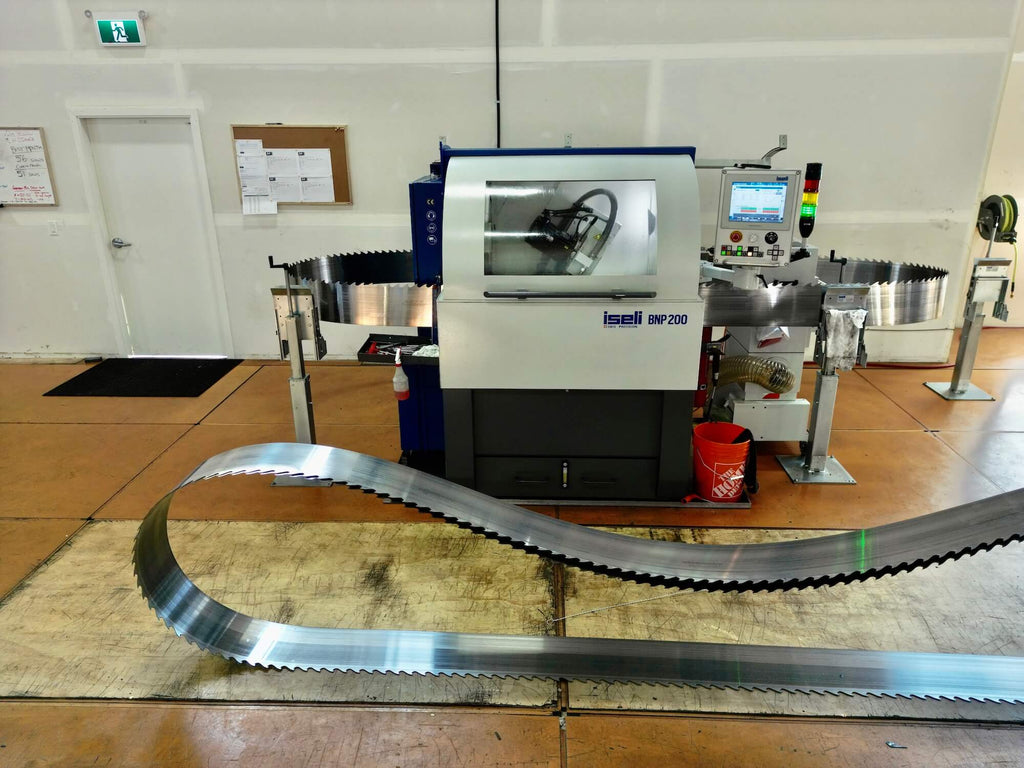

AKD Caboolture Iseli- BNP200 Bandsaw grinders .

Aaron McRae from Thode Knife & Saw Pty Ltd commissioned two new Iseli BNP200 Bandsaw Sharpeners replacing ageing Vollmer Sharpeners.

This compliments the Iseli RZ1 which was installed in December 2023

Iseli Machines commissioned at Interfor Adams Lake, BC

The Iseli BNP200 CNC bandsaw profile grinder was installed in January 2024. Interfor have done successful trials with variable pitch bandsaws which justified upgrading to a CNC machine providing proportional variable pitch and depth tooth

pattern saws.

Above: Warren Upton and Wayne Gerlitz

Below: Ray Jackson, head filer (left), with Jason Jagt and Mike Wutzke

A much sharper saw is achieved with the CBN grinding wheels with flood oil coolant.

The Iseli RZ1 benching station was installed at Interfor Adams Lake, BC. in April 2024

Below: James Tones (left) and David Toews, lead hand.

Rosvall Sawmill - looking to the future

Rosvall Sawmill are one of the latest sites to conduct a saw trial of the Thode VPD profile, with outstanding results!

Two saws were designed, manufactured, and delivered to site for the trial to commence, each saw was run for a total of 3 hours as these were brand new, and a short run is always recommended.

The standard pitch saw was taken off at the last smoko and the Thode VPD saw put on to finish the day, the improvement was noticed instantly by the operator who commented how quiet and smooth cutting the saw was.

The Rosvall team have a great curve catcher display and recording system so there was no mistaking the results for gut feel, these were crystal-clear, real-time results.

While the first saw trial was in full swing, Mark Hansen, Rosvall Sawmill Managing Director joined us in the Headrig cab, asking the operator what he thought, looking at the data displayed in front of him and asking the Thode team questions.

You could see the excitement in his eyes as he timed each cut while looking at how well the saw was performing and very quickly converting this information into dollars in his head.

Knockoff rolled around, it was a great end to the day with the first saw to be trailed an undeniable success!

Day two, on went the second Thode VPD saw and what a surprise…. actually…. there was no surprise, this saw preformed just as exceptionally as the first!

Before the second saw had completed its run the deal was sealed with handshake and an Iseli BNP100

2 axis bandsaw profile grinder was ordered on the spot!

There was also an order for another two Thode VPD saws placed with a plan for all of these to be serviced at Thode’s Rotorua factory while waiting for the new grinder to arrive.

After running the new saws regularly, it became very clear, very quickly that these were the best performing saws that the mill had ever seen, even on the harder to cut logs that the mill encounters from time to time.

More saws were ordered in very quick succession with the total now at 10, with these replacing the standard pitch saws and being run full time as the gains for the sawmill production and quality were far too good to wait for the new machine to arrive.

“We enjoy working with Thode to harness modern technology. We are impressed with their knowledge and skill that they so willingly share with us in a timely manner.

Through working with Thode, we have experienced immediate impressive results. The change to working with Thode’s modern technology and precision saw making has given us a 15% lift in sawing speed with noticeable gains in sawing accuracy and blade performance.

The technology lift in the sawmill has been quite revolutionary for our team, we’re excited to continue the journey of continuous improvement with Thode.” - Rosvall Managing Director, Mark Hansen.

With their new Iseli BNP100 profile grinder scheduled to arrive mid-May 2024, the saw shop team at Rosvall sawmill are getting pretty excited to start using their new toy after having the opportunity to operate the same machine at Thode’s Rotorua factory over a three-day training session earlier this year.

Thode Knife & Saw would like to take this opportunity to thank the Rosvall team for their support and enthusiasm. We are as excited and passionate as you all are to be a part of your journey into the future.

New Iseli Machines at Thode Knife and Saw Manufaturing Site Rotorua NZ

THODE KNIFE & SAW’s: latest machine installations.

The latest install to the THODE Band saw manufacturing plant at 316 Te Ngae Road Rotorua

Two new top of the line Iseli machines, the BNF 100 side grinder and the BNA100 Plasma tipper

These machines are two of the very latest top of the range machine centres supplied by Iseli in Switzerland

Thode are the very proud suppliers of these innovative machines to the saw milling industry.

The BNF100 side grinder

The BNF100 side grinder is capable of side grinding your saws to within several microns per side.

Saw tooth accuracy on both sides is without doubt critical.

So often the side grinding of a saw will let the saw down, tooth geometry is a critical aspect of saw performance and we need to get it right.

We all know tooth geometry is first and foremost. Tangential and radial angles are critical for fast straight cutting, these machines achieve that goal.

The accuracy of these machine centre is outstanding. Thode now have two of these installed in our factory so you can be reassured your saws are in spec and ready to cut fast and hard.

The BNA plasma tipper

The BNA plasma tipper is the latest from Iseli.

This machine melts the tip material into copper contact cups, providing us with the ability to trial various metals not only Stellite to optimise saw performance for very different applications.

This machine compliments the tipping capabilities of Thode Knife and Saw and sits alongside our two Iseli SAA tippers.

Thode Knife and Saw constantly work with our customer base to get the very best saw performance out of their operation.

Thode is Innovative in the saw design of both Bandsaws and Circular saws, water cutting tooth profile of variable pitch and depths to finite accuracy, these new machines compliment our manufacturing operation

Taranakipine Saw Shop Upgrade Project

The Taranakipine saw shop upgrade project all started with a conversation about a saw trial on site of the Thode designed Variable Pitch & Depth profile with the dream of the projected gains in productivity paying for a state-of-the-art re-fit.

The Thode VPD profile differs from the more traditional ascending and descending patterns that had been more commonly used over the years, by using an alternate layout of the pitching to create a wave looking profile further enhancing the effects of the VPD concept.

Working with Taranakipine’s saw shop contractor, Craig Robinson of Fred Robinson Saw Doctors and sawmill manager Rodney Baker, the trial got the go ahead and two saws were ordered “ready to run” meanwhile Craig and Rodney set about gathering as much information as they could to form solid base line data of where the sawmill was currently performing.

In mid-September 2021, the Thode VPD saws arrived on site and the trial was underway.

There was noticeable difference in performance instantly and at the end of the trial with all the data collected the improvement in sawmill performance was significant!

This information along with a list of the top-of-the-line Iseli machinery for a full saw shop fit out was then presented to John Sanders, Taranakipine’s Plant and Projects manager so the numbers could be crunched for justification.

The capex put together by John and his team flew through board approval and the order for the Iseli machinery was placed.

Meanwhile we set to work planning the new saw shop layout. We used 3D models of the Iseli machinery to generate several floor plans for different layout options, and through consulting with Craig we found the perfect layout to maximize space and flow through the saw shop for what he and the team needed for ease of day-to-day operation.

The team had a goal of “zero” sawmill down time for this project and to accomplish this we had to have a bullet proof installation plan, the timing and order of existing gear to be removed and the order that the new gear would be positioned and powered up would have to be perfection.

Working with Craig and the Taranakipine maintenance team we crafted just that, removing as much of the old gear to give the floor reconditioners and painters as much time and space as possible before the new Iseli equipment arrived on site.

In November 2023 five pieces of Iseli equipment arrived on site, this consisted of one RZ1 auto benching station, an SAA Stellite tipper, a BNF100 5 axis CNC side grinder and two BNP110 2 axis CNC profile grinders.

The plan worked like clockwork, perfectly staged to maximize time for all trades involved.

Week one, the SAA, BNF and both BNP grinders were installed, power on and sharpening saws.

Week two, the last of the old gear removed and the RZ1 installed, tuned and training on all machinery commenced.

While this was a big task the “zero” mill down time goal was achieved with the sawmill never missing a beat! Something that everyone involved can be extremely proud of!

At the start of week two, now with both BNP110’s up and running the new Thode VPD saws were unleashed on the mill and very quickly the gains become apparent! So much so that we had barely started the week and the operators no longer wanted the old standard pitch saws and Rodney made the call that they were to no longer to be used!

“We got everything up and running in the first week of November 2023. From that point on we noticed the difference in cutting speeds, sawing accuracy improvement, cleaner cutting no feather edges, less reprocessing due to accuracy of cutting, less intermittent saw changes, quieter cutting, motivation of saw doctors and production crews around upgrade of saw shop having new gear and technology in the saw shop. With wet grinders it made a huge difference to the air quality and the housekeeping was made easier as well with everything being contained. Overall, we are well on track to hit our targets for the payback time of this install. Thanks to all parties involved.” Rodney Baker- Sawmill Manager.

BEFORE & AFTER

A night & day difference, not only in presentation but in performance too!!

After a few months of running and the sawmill operation staff having the time to settle in, it has become clear that there have been gains in several areas as Rodney has mentioned above.

It is important to note that the only thing changed in the sawmill at this time was going from a standard pitch profile to the Thode VPD profile on all band saws.

The trial was a great success, testing in a controlled environment, removing as many variables as possible with the data recorded clearly showing that if you want a way to pay for your brand-new saw shop this is the way to accomplish it!

Thode 100% recommend and stand behind the Thode VPD profile as the best option for sawmills to maximize productivity and drastically reduce their manufacturing cost / M3 making their business more profitable.

We would like to take this opportunity to thank the team at Taranakipine for putting their trust in Thode to deliver another successful Iseli installation.

The new Saw Shop is light and bright with the new layout spacious and user friendly.

"All I can say is that the accuracy is Awesome! And the Iseli gear is very easy to

use” - Craig Robinson

BELOW: Craig operating the new Iseli BNF100 side grinder. The BNF side grinds each tooth from start to finish using multiple passes which means the saw only has to do one full lap.

BELOW: Craig & Darryl with the Iseli RZ1 auto bench

If you are interested in more information on the Iseli range of saw shop machinery or would like to talk about conducting your own Thode VPD saw trial, feel free to contact us at any time.

A Positive Move For Thode Knife & Saw Ltd Christchurch.

As of 1st July 2023 Thode Knife & Saw Christchurch started the move to a new building better suited to our current size and customer base. The previous building had been fit for purpose for 25+ years and as the industry changed, the need for such a big building didn’t fit our needs going forward.

We are now situated at 29A Blakes Road, Belfast in a new building that we had some input into the design and layout of the office / store and staff amenities and are now firmly placed to service our customers from this site. Our staff are over the moon to have a new building and bright and airy working conditions. “The move gave us the ability to create a much better, more efficient factory layout and introduce new machinery in a controlled well-planned manner.

During the planning stage of the move we decided to upgrade an area of our factory to meet the current needs of our customer base, namely our Tungsten Carbide (TCT) circular saw servicing area. The TCT area now has a fully automated circular saw grinder that is fitted with a self-loading arm. This machine has replaced two Vollmer CX100’s and increased our ability to service our customers saws 50% faster and saws serviced to date are showing a great level of both accuracy and sharpness. The robotic combination means when we have high levels of saws for servicing we can stack and load the trolleys and set the machine to run overnight so when we arrive in the morning all saws are sharp and ready to go back to the customers.

Latest Iseli RZ1 installation AKD Caboolture Queensland.

Aaron McRae recently commissioned the Iseli RZ1 benching Station at AKD Caboolture Queensland.

This is the first stage of their Sawshop Machinery upgrades to further the Sawmills performance.

Aaron would like to thank Neil Hunter, Robert Dunn and the Team in the Sawshop.

Recent Machine Upgrade at Pan Pac Otago

As part of a continuous improvement programme, Pan Pac Otago recently installed an Iseli KHF100 circular saw side grinder into the Milburn site sawshop. The KHF100 replaced an older North American machine that had worked well on site for many years but had reached its end of serviceable life.

Both Pan Pac’s sites have an array of Iseli equipment already, so the decision was made to replace the existing side grinder with an Iseli KHF100 Fully automatic 6 axis CNC machine. The KHF100 is designed for fully automatic grinding of the side angles on Carbide/Stellite tipped circular saws, and features space saving machine design that allows for high ergonomics and excellent usability, as well as ease of access to the electrical cabinet, coolant pump, pneumatics and fire suppression system.

Other notable features are:

Other notable features are:

- automatic adjustment of all common angles

- automatic detection of the tooth pitch with built in sensor technology on the feed finger

- the ability for the positioned tooth to be finished in several passes (saw finish ground in one rotation)

- high flow capacity oil coolant

- automatic CO2 fire detection and supression system.

The machine is controlled via a 15.1 inch colour touch screen with Windows-based interface for fast saw parameter loading and has unlimited program storage.

The grinder was installed in November 2023 and commisioning and training was completed by Regan Eisenhut from Thode Knife & Saw Rotorua.

Thode Knife & Saw would like thank the team at Pan Pac Otago for choosing the Iseli machine and the help given to Regan while commisioning and training.

For any further information regarding the range of Iseli Sawshop/ Filing room equipment contact your Thode sales rep.

Centrifugal Mobile Cleaning Station

Thode Knife & Saw Auckland recently purchased a mobile cleaning station marketed by Iseli.

The centrifugal system gives superior cleaning of oil coolant over their older filter system which was fitted to their manufacturing centre.

When the machine was first connected to the top and face grinder the coolant was at a stage that it was due for a full change. After running the centrifuge for a week, the coolant was back to its near original colour.

They now rotate the RUMA on all their machines.

Darren Clissold, Auckland Production Manager, is thrilled with both the efficiency of the cleaner and the massive cost savings from not having to replace the specialized grinding oils they run in their machines.

He also enjoys the ease of set-up and the lock out switch which means the machine complies with H&S requirements.

Thode Canada and OFO Australia are also thrilled with the operation of their RUMA cleaning units

Contact your THODE REP to find out more about these machines.

THODE TO SUPPLY UDDELHOLM BANDSAW STEEL

Thode Knife and Saw are extremely proud to have secured a supply agreement with voestalpine for the supply of Uddeholm bandsaw steel.

As a result Thode will be supplying all wide bandsaws using the Uddeholm brand. We are excited to have this strong relationship and once stocks of our other brands of bandsaw steel run out we will be transitioning 100% to the Uddeholm brand.

This rationalisation of our bandsaw steel supply will create better raw material planning, and improved logistics in order for Thode to provide continued on time delivery of quality product to our valued customers.

We still have some inventory on hand of existing bandsaw steel so we will continue to supply your currently purchased brand on a stock item basis while stocks last, then transition to Uddeholm.

We trust that this progression will be seen as a positive move with the Thode supply of bandsaws to the Australian and New Zealand markets.

Above from left while at Ligna May 2023:

Kevin Parker

(Director - Thode Knife & Saw),

Christian Peterlechner

(Sales Director Saw Steel - voestalpine Austria)

Aaron Hartley

(Sales & Customer Service Manager - Thode Knife & Saw)

Christchurch branch address update

Please note, as of 03/07/23 our CHCH branch is at a new location

29A Blakes Rd

Belfast

Christchurch

Happy Customers in Quebec Canada

Thode Knife & Saw and Iseli thank Scierie St-Armand, Quebec on their purchase of their Iseli BNP200 Profile Grinder. The BNP200 is one of the most advanced Bandsaw Profile Grinder available and is becoming first choice amongst advanced Sawmills in Canada. Pictured is Renald Yergeau with his New Iseli BNP200. Renald is head filer (left) with Phil Higgins (Manager Thode Knife & Saw Canada) who completed the commissioning.

Thode Knife & Saw & Iseli also thank Affutage JL at St-Pamphile, Quebec on their purchase of a new Iseli RZ1. Kathy Pelletier on the left and Christopher Gagnon on the right with their new RZ1.

The Iseli RZ1 is the worlds biggest selling Automatic Levelling & Tensioning machine and is a great addition to their filing room.

One Forty One Jubilee Highway Australia BNP200 Left & Right Hand Bandsaw Grinders

One Forty One Jubilee Highway BNP200 Left & Right Hand Bandsaw Grinders Installation

December 2022

Aaron McRae & Regan Eisenhut Commissioned two new Iseli BNP200s with the latest Tooth Tracing System for One Forty One Jubilee Highway Sawmill in Mt Gambier South Australia.

These two machines will now complement the recently installed RZ1, BNF100 side grinder and SAA stellite tipper as part of their major capital investments in the Sawshop.

Aaron McRae (Thode) Mauro Rossi and Matt Bowering (OFO) going into the screen settings on the BNP200

Thode Knife & Saw Pty would like to Thank OFO for their ongoing support of the Iseli products.

Special Thanks to Barry Kuhl, Matt Bowering and staff for your Hospitality.

Aaron & Regan.

Iseli Machinery commissioning in Canada Dec 2022

Over the past 12 months our CA customers have been anxiously awaiting the arrival of their new Iseli sawshop equipment.

After successful comissioning, it's all smiles for this group of discerning buyers.

Thode and Iseli thank you for your continued support.

Iseli principle Philipp Iseli visits Thode Canada’s manufacturing plant in Chilliwack BC

From left Philipp Iseli CEO Iseli Swiss Precision, Phillip Higgins Manager Thode Knife & Saw Canada, Kevin Parker CEO Thode Knife & Saw

Thode now in its fourth year providing filing-room solutions with Iseli Machinery and saw blades in Canada after expanding from Australasia where it has been operating for over 75 years. Iseli also in business for over 75 years has had a collaborating partnership with Thode for over 20 years in Australasia and since the inception of Thode Canada.

Our Canadian customers are very supportive of the world class technology being offered by Thode Canada. We have a growing order book of Iseli machines which follow on from installation’s that have proven to increase efficiencies in filing rooms across Canada.

Our bandsaw manufacturing plants also use the latest technology featuring Iseli equipment which is giving customers Canadian made saws of the highest standard and consistency using renown Uddeholm 000 material.

We would like to thank our customers for their support giving us confidence to build a new manufacturing plant in BC and we look forward to building on the relationships and business that is growing as a result.

|

|

Please direct your enquiries to Mr Phillip Higgins our Thode Canada Manager.

Tel: +1 (778) 684-6078

Email: phil@thodecanada.ca

Iseli BNP200 featured on BC Saw Filers Convention 2022

Phil shows off an Iseli BNP200 bandsaw profile grinder at the BC Saw Filers Convention 2022.

Link to Canadian Forest Industries article here.

Iseli RZ-1 Installation at Freeman Lumber Nova Scotia

Kendall Lawson of Freeman Lumber Nova Scotia stands proud of his new Iseli RZ1 Auto Bench. This was commissioned by Regan Eisenhut (Operations Manager from Thode Knife & Saw). The Iseli RZ1 is the benchmark of Bandsaw Auto Level & Tension Machines available in the world today.

If you are wanting high efficiency and consistency in your filing room contact Thode Knife & Saw to discuss the benefits this machine will give your Sawmill.

Thode Knife & Saw would like to thank Freeman Lumber for their purchase.

Kendall Lawson of Freeman Lumber Nova Scotia

Downie Timber invests in Iseli BNP 100 CNC Bandsaw Profile Grinder

Phil Higgins (Thode Canada Manager) recently commissioned an Iseli BNP100 CNC bandsaw profile grinder for Downie Timber

Heath Hanson (pictured) the head filer at Downie Timber in Revelstoke BC Canada stands proud with the new BNP100 grinder which has just been installed.

This is a new filing room in their Selkirk Cedar plant where a variety of saw specifications are catered for as used in the production process.

Thode Knife & Saw Ltd thank Downie Timber for choosing Iseli equipment for their filing room. Iseli has become a brand of choice for many leading companies throughout the world due to the technology, precision and reliability which gives customers assurance of improved quality and efficiency.

Australia

Australia

Canada

Canada